Universal foam adhesive for various construction works indoors and outdoors. Usable all year around ensuring good results at temperatures from -5 up to + 30 °C. Foam adhesive has great gluing and thermal insulation properties, low curing pressure and low post expansion. Adheres well to most materials like polystyrene, plasterboards, OSB, chipboard, wood, concrete, stone, metal and PVC.

Features:

- Great gluing properties

- Suitable for all season use, from 23°F up to 86 °F

- Low curing pressure and post expansion

Field of applications:

- Field of applications

- Fixing of insulation boards on facades and foundations

- Fixing of interior design boards

- Fixing of window sills

- Gluing of construction blocks

- Reducing the impact of thermal bridges

APPLICATION INSTRUCTIONS:

Surface preparation: Remove dust, loose particles and grease from the surfaces. Moisten dry substrate to ensure better results.

Application temperatures:

- Air temperature during use: 23°F to 86°F , best results at 77°F.

- Can temperature during application: 41°F to 77°F, best results at 68 °F.

- Foam can has to be warmed with water or air (max. 86°F) before starting work in low temperatures.

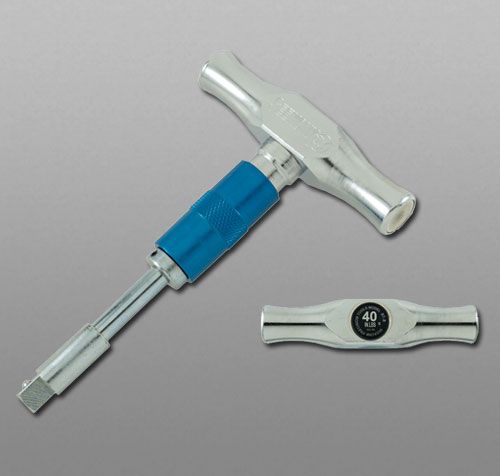

Application with foam gun: Shake the can vigorously at least 20 times. Hold the foam can in upright position, turn the gun to the can by holding the gun handle with one hand, and turn the can with the other hand. Make sure that the gun is not pointed at other persons when turning it. The can must not be screwed to the gun with the valve upside down or by turning the gun on the can. The foam output can be adjusted by the gun trigger.

Instructions for gluing insulation boards and interior design boards: Apply the foam adhesive to boards as an even flow, parallel with the sides of the board (3-4 cm from the edge) and one strip in the middle, parallel to the longest side (up to 25 cm between adhesive strips). After applying the foam adhesive to the board wait 2-3 minutes and then press the board to the wall. The level of installed boards can be adjusted within up to 5 minutes. Output (for 750 ml) when fixing insulation boards is 10 m2 of wall surface.

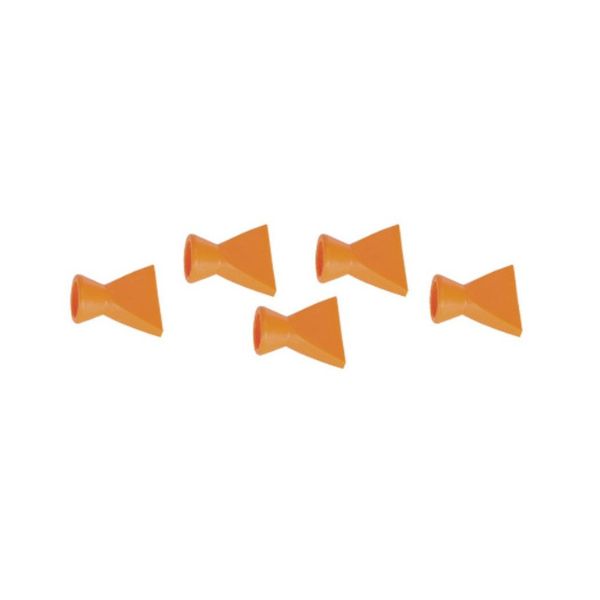

The foam adhesive has sufficient strength for fixing insulation boards. Always follow building design, building regulations, standards or other relevant guidelines concerning additional mechanical fastening when covering insulation boards with cladding materials. Use of insulation support anchors is always recommended.

In general it is not recommended to use this product on bituminous surfaces. In some cases, e.g. fixing insulation boards on bitumen treated foundations before backfilling, the product has sufficient adhesion. Always test before use.

Fixing of window sills: Before fixing the window sill make sure that the base surface is leveled. Spacers must be used to support the window sill; foam can only be used as an adhesive. Apply foam adhesive to the base surface 3-4 cm from the edge. Weights must be used to fix the window sill until the foam adhesive is cured.

Gluing of construction blocks: Foam adhesive can be used for non-bearing interior walls. Consult a sales agent, a dealer or an architect regarding compatibility with various stone-based materials and other technical issues. First row of blocks must be well leveled using mortar. Substrate should be moistened as the foam cures due to moisture. A moistened surface ensures better results. Foam adhesive should be applied to both vertical and horizontal surfaces. Wait for a few minutes after applying the foam adhesive and then press the stone surfaces together. Foam adhesive can be used only in case even distribution of loads from block to block is ensured. Not suitable for distributing or carrying loads.

Cleaning: Uncured foam can be removed with acetone, cured foam with mechanical means.

Storage Conditions: Guaranteed shelf life is 12 months from production date if stored in unopened packaging in a cool and dry place at 23°F to 86°F . The fo cans must not am be stored above 122° F, nearby heat sources or in direct sunlight. Store and transport in a vertical position.

For best results when spraying Seal Spray Foam in an overhead application, please use our angled gun - Item # SEALGUNA1

Features and Benefits:

- Excellent Adhesion

- Low Cost Per Yield

- Seals Air Gaps

Applications:

- Drywall Panel Installation

- Adheres To Wood, Metal and Glass

Specs:

- Can Size: 24 oz

- Yield Per Can: 375+ linear feet with bead 1/2" or smaller

- R-Value @ 1": N/A

- Closed Cell Content: N/A

- Shelf Life in Months: 24

.jpg)